Advantages of Next-Generation Flex Rigid PCBs

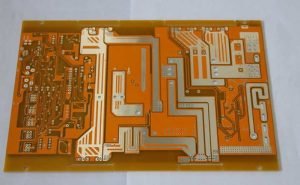

Flex rigid PCBs, also known as flexible printed circuit boards, are revolutionizing the electronics industry with their unique design and capabilities.

These next-generation PCBs combine the flexibility of a flexible PCB with the rigidity of a traditional rigid PCB, offering a wide range of advantages over conventional circuit boards.

One of the key advantages of next-generation flex rigid PCBs is their ability to reduce space and weight in electronic devices.

By eliminating the need for bulky connectors and cables, these PCBs allow for more compact and lightweight designs, making them ideal for portable and wearable electronics. This reduction in size and weight also contributes to improved overall performance and efficiency of electronic devices.

In addition to space and weight savings, next-generation flex rigid PCBs offer enhanced reliability and durability.

The flexible nature of these PCBs allows them to withstand bending and twisting without compromising their functionality, making them ideal for applications where mechanical stress is a concern. This increased durability also translates to longer product lifecycles and reduced maintenance costs, providing a significant advantage for manufacturers and end-users alike.

Furthermore, next-generation flex rigid PCBs enable more complex and innovative designs that were previously not possible with traditional circuit boards. The ability to incorporate multiple layers, components, and interconnects in a single board allows for greater design flexibility and customization, leading to improved performance and functionality of electronic devices. This versatility also opens up new possibilities for product development and innovation in various industries.

Another advantage of next-generation flex rigid PCBs is their cost-effectiveness. While the initial manufacturing costs may be higher compared to traditional circuit boards, the long-term benefits of reduced maintenance, improved reliability, and enhanced performance outweigh the upfront investment. Additionally, the ability to streamline production processes and reduce assembly time with flex rigid PCBs can result in overall cost savings for manufacturers.

Moreover, next-generation flex rigid PCBs offer improved signal integrity and electromagnetic compatibility, thanks to their reduced electromagnetic interference and crosstalk. This results in better signal transmission and reception, leading to enhanced overall performance and reliability of electronic devices. The high-density interconnects and fine-pitch components in flex rigid PCBs also contribute to improved signal quality and reduced signal loss, further enhancing the functionality of electronic devices.

In conclusion, next-generation flex rigid PCBs are pioneering the future of electronics with their numerous advantages over traditional circuit boards.

From space and weight savings to enhanced reliability and durability, these PCBs offer a wide range of benefits that are driving innovation and advancement in the electronics industry. With their ability to enable complex designs, reduce costs, and improve signal integrity, flex rigid PCBs are poised to become the standard for electronic devices of the future.