Benefits of Flex Rigid PCBs in Electronic Devices

Flex rigid PCBs, also known as flexible printed circuit boards, are revolutionizing the world of electronic devices.

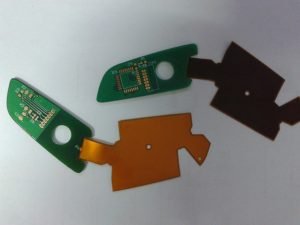

These innovative circuit boards offer a unique combination of flexibility and rigidity, making them ideal for a wide range of applications.

From smartphones and wearables to medical devices and automotive systems, flex rigid PCBs are changing the way we think about electronic design.

One of the key benefits of flex rigid PCBs is their ability to bend and twist without compromising performance.

Traditional rigid PCBs are limited in their flexibility, which can be a major drawback in applications where space is limited or where the circuit board needs to conform to a specific shape. Flex rigid PCBs, on the other hand, can be bent, folded, and twisted to fit into tight spaces or conform to complex shapes, making them ideal for compact electronic devices.

In addition to their flexibility, flex rigid PCBs offer improved reliability and durability compared to traditional rigid PCBs.

The flexible portions of the circuit board are less prone to cracking or breaking under stress, making them more resistant to mechanical

shock and vibration. This increased durability can help extend the lifespan of electronic devices and reduce the need for costly repairs or replacements.

Another advantage of flex rigid PCBs is their ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, flex rigid PCBs can help designers create sleeker, more compact devices without sacrificing functionality. This can be especially beneficial in applications where space is at a premium, such as in wearable technology or IoT devices.

Flex rigid PCBs also offer improved signal integrity and electrical performance compared to traditional rigid PCBs.

The flexible portions of the circuit board can help reduce signal loss and impedance mismatch, leading to more reliable and consistent performance.

This can be critical in high-speed applications where signal integrity is paramount, such as in data centers or telecommunications equipment.

Furthermore, flex rigid PCBs can help streamline the manufacturing process and reduce production costs.

By combining the flexibility of a flexible circuit with the rigidity of a traditional PCB, designers can simplify the assembly process and

reduce the number of components needed. This can lead to faster production times, lower labor costs, and overall cost savings for manufacturers.

Overall, the future of electronic devices is looking more flexible thanks to the potential of flex rigid PCBs. These innovative circuit boards offer a unique combination of flexibility, reliability, and performance that can help designers create smaller, lighter, and more reliable devices. Whether it’s in smartphones, wearables, medical devices, or automotive systems, flex rigid PCBs are poised to revolutionize the way we think about electronic design.