Benefits of Rigid Flex PCBs

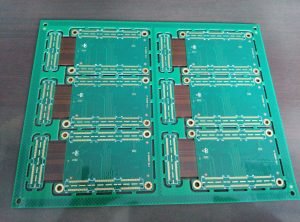

Flexible circuit technology has revolutionized the electronics industry, allowing for the creation of products that are smaller, lighter, and more durable than ever before. One of the most exciting advancements in this field is the development of rigid flex PCBs, which combine the flexibility of traditional flexible circuits with the rigidity of traditional printed circuit boards. This innovative technology offers a wide range of benefits that make it an attractive option for a variety of applications.

One of the key advantages of rigid flex PCBs is their ability to reduce the overall size and weight of electronic devices. By combining the flexibility of a flexible circuit with the rigidity of a printed circuit board, designers can create products that are more compact and lightweight than ever before. This is particularly important in industries such as aerospace, where every ounce of weight savings can make a significant difference in fuel efficiency and performance.

In addition to their compact size and lightweight construction, rigid flex PCBs also offer improved reliability and durability compared to traditional flexible circuits. The rigid sections of the PCB provide support and protection for the flexible sections, reducing the risk of damage from bending or flexing. This makes rigid flex PCBs ideal for applications where the circuitry is exposed to harsh environmental conditions or frequent movement.

Another benefit of rigid flex PCBs is their ability to simplify the assembly process. By combining multiple PCBs into a single unit, designers can reduce the number of interconnects and solder joints required, which can help to improve overall reliability and reduce the risk of assembly errors. This can also lead to cost savings, as fewer components and less labor are required to assemble the final product.

Rigid flex PCBs also offer greater design flexibility compared to traditional PCBs. Designers can create complex, three-dimensional shapes that would be impossible with a rigid PCB alone, allowing for more creative and innovative product designs. This flexibility also extends to the placement of components, as designers can place components on both the rigid and flexible sections of the PCB to optimize performance and functionality.

In addition to their technical advantages, rigid flex PCBs also offer cost savings over traditional PCBs in many cases. While the initial cost of manufacturing rigid flex PCBs may be higher than that of traditional PCBs, the overall cost of the final product can be lower due to reduced assembly time, fewer components, and improved reliability. This makes rigid flex PCBs a cost-effective solution for many applications, particularly those where space and weight savings are critical.

Overall, rigid flex PCBs offer a wide range of benefits that make them an attractive option for a variety of applications. From their compact size and lightweight construction to their improved reliability and durability, rigid flex PCBs are shaping the future of flexible circuit technology. With their ability to simplify the assembly process, offer greater design flexibility, and provide cost savings, rigid flex PCBs are poised to revolutionize the electronics industry and drive innovation in a wide range of industries.