Benefits of Using Rigid Flex PCBs in Consumer Electronics

Printed circuit boards (PCBs) are an essential component in the manufacturing of consumer electronics.

They provide the necessary electrical connections between components, allowing devices to function properly.

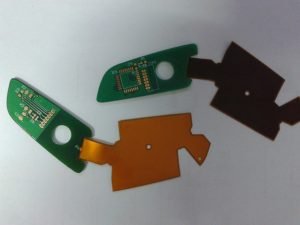

In recent years, there has been a growing trend towards the use of rigid flex PCBs in consumer electronics.

These innovative PCBs offer a number of benefits over traditional rigid or flexible PCBs, making them an attractive option for manufacturers looking to improve the performance and durability of their products.

One of the key benefits of using rigid flex PCBs in consumer electronics is their ability to reduce the overall size and weight of devices.

By combining rigid and flexible PCBs into a single unit, manufacturers can create more compact and lightweight designs, allowing for sleeker and more portable devices. This is particularly important in industries such as smartphones and wearables, where consumers are increasingly demanding smaller and more lightweight products.

In addition to their compact size, rigid flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The flexible portions of the PCBs are able to withstand bending and flexing without compromising the integrity of the electrical connections, making them ideal for devices that are subject to frequent movement or vibration. This increased durability can help to extend the lifespan of consumer electronics, reducing the need for costly repairs or replacements.

Another benefit of using rigid flex PCBs in consumer electronics is their ability to improve signal integrity and reduce electromagnetic interference.

The rigid portions of the PCBs provide a stable platform for components, while the flexible portions allow for greater flexibility in routing signals.

This can help to minimize signal loss and distortion, resulting in improved performance and reliability for electronic devices.

Additionally, the shielding properties of rigid flex PCBs can help to reduce electromagnetic interference, ensuring that devices operate smoothly even in environments with high levels of electromagnetic noise.

Furthermore, rigid flex PCBs offer greater design flexibility compared to traditional PCBs. Manufacturers can create complex and intricate designs that would be difficult or impossible to achieve with rigid or flexible PCBs alone.

This flexibility allows for more creative and innovative product designs, giving manufacturers a competitive edge in the fast-paced consumer electronics market.

Overall, the growing popularity of rigid flex PCBs in consumer electronics can be attributed to their numerous benefits, including reduced size and weight, improved reliability and durability, enhanced signal integrity, and greater design flexibility.

As consumers continue to demand smaller, more reliable, and more innovative electronic devices, manufacturers are turning to rigid flex PCBs as a solution to meet these demands.

By incorporating rigid flex PCBs into their product designs, manufacturers can create cutting-edge devices that offer superior performance and durability, setting themselves apart in a highly competitive market.