Benefits of Using Rigid Flex PCBs in Electronics Design

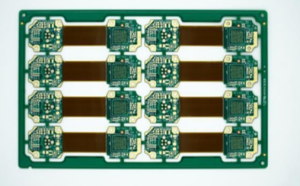

Rigid-flex PCBs, or printed circuit boards, have become an increasingly popular choice for designers looking to create complex electronic devices. These boards offer a unique combination of flexibility and rigidity, allowing for more creative and efficient designs. In this article, we will explore the benefits of using rigid-flex PCBs in electronics design.

One of the key advantages of rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices. By combining rigid and flexible materials in a single board, designers can create compact and lightweight products that are easier to transport and handle. This can be particularly useful in applications where space is limited, such as in wearable technology or medical devices.

Another benefit of rigid-flex PCBs is their durability and reliability. The flexible portions of the board are designed to withstand bending and twisting without compromising the integrity of the circuitry. This makes rigid-flex PCBs ideal for applications where the board may be subjected to mechanical stress or vibration. Additionally, the use of rigid materials in key areas of the board helps to protect sensitive components from damage.

In addition to their physical durability, rigid-flex PCBs also offer improved electrical performance. The use of flexible materials allows for more efficient routing of traces and connections, reducing signal loss and interference. This can result in better overall performance and reliability of the electronic device. Furthermore, the rigid portions of the board provide a stable platform for mounting components, ensuring that they remain securely in place.

One of the most significant benefits of using rigid-flex PCBs is the potential for cost savings. While the initial manufacturing costs of rigid-flex PCBs may be higher than traditional rigid boards, the overall savings can be substantial. By eliminating the need for additional connectors and cables, designers can reduce the number of components and assembly steps required, leading to lower production costs and faster time to market.

Furthermore, the use of rigid-flex PCBs can also simplify the design process. Designers have more flexibility in creating custom shapes and configurations, allowing for more creative and innovative designs. This can lead to improved functionality and aesthetics in the final product. Additionally, the reduced number of interconnects and solder joints can result in a more reliable and robust design.

Overall, rigid-flex PCBs offer a versatile solution for complex electronics designs. Their unique combination of flexibility, durability, and performance make them an attractive choice for a wide range of applications. Whether you are designing a wearable device, a medical instrument, or a consumer electronics product, rigid-flex PCBs can help you achieve your design goals efficiently and effectively. With their numerous benefits, it is clear that rigid-flex PCBs are here to stay as a key technology in the world of electronics design.