Benefits of Using Rigid Flex PCBs in Automotive Electronics

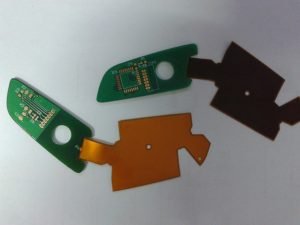

Rigid flex PCBs, or printed circuit boards, have become an essential component in the automotive industry, enabling innovation and advancement in electronic

systems within vehicles. These specialized PCBs offer a unique combination of flexibility and rigidity, allowing for more compact and efficient designs that can withstand the harsh conditions of automotive environments. In this article, we will explore the benefits of using rigid flex PCBs in automotive electronics.

One of the key advantages of rigid flex PCBs is their ability to reduce the overall size and weight of electronic systems in vehicles.

By combining rigid and flexible sections in a single board, designers can create more compact and streamlined layouts that take up less space in the vehicle. This not only allows for more efficient use of space within the vehicle, but also helps to reduce the overall weight of the electronic systems, contributing to improved fuel efficiency and performance.

Additionally, the flexibility of rigid flex PCBs allows for greater design flexibility and customization in automotive electronics.

Designers can create complex, three-dimensional shapes and configurations that would be impossible with traditional rigid PCBs.

This flexibility enables the integration of multiple components and functions into a single board, reducing the need for additional wiring and connectors.

This not only simplifies the assembly process, but also improves reliability and durability by reducing the number of potential points of failure.

Another benefit of using rigid flex PCBs in automotive electronics is their ability to withstand the harsh conditions of automotive environments.

Vehicles are exposed to extreme temperatures, vibrations, moisture, and other environmental factors that can damage or degrade electronic components. Rigid flex PCBs are designed to be more durable and reliable than traditional PCBs, with the ability to withstand temperature fluctuations, mechanical stress, and moisture ingress without compromising performance. This makes them ideal for use in automotive applications where reliability and longevity are critical.

Furthermore, rigid flex PCBs offer improved signal integrity and electrical performance compared to traditional PCBs.

The combination of rigid and flexible sections in a single board helps to reduce signal loss and interference, resulting in more stable and reliable electrical connections. This is especially important in automotive electronics, where high-speed data transmission and precise control are essential for safety and performance. Rigid flex PCBs can help to ensure that electronic systems in vehicles operate efficiently and accurately, even in challenging conditions.

In conclusion, the benefits of using rigid flex PCBs in automotive electronics are clear.

These specialized PCBs offer a unique combination of flexibility, durability, and performance that make them ideal for use in the demanding environments of

vehicles. By enabling more compact and efficient designs, improving reliability and signal integrity, and withstanding harsh conditions, rigid flex PCBs are helping to drive innovation and advancement in automotive electronics. As the automotive industry continues to evolve and embrace new technologies, rigid flex PCBs will play an increasingly important role in shaping the future of electronic systems in vehicles.