Benefits of Using Rigid-Flex Printed Circuits in Aerospace Industry

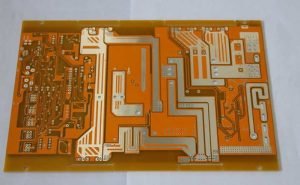

Rigid-flex printed circuits have become an essential component in various industries due to their flexibility, durability, and reliability.

One industry that has greatly benefited from the use of rigid-flex printed circuits is the aerospace industry. These circuits have revolutionized the way electronic systems are designed and integrated into aircraft, spacecraft, and satellites.

One of the key benefits of using rigid-flex printed circuits in the aerospace industry is their ability to withstand harsh environmental conditions.

Aircraft and spacecraft are exposed to extreme temperatures, vibrations, and pressures during flight. Rigid-flex printed circuits are designed to be highly durable and reliable, making them ideal for use in these demanding environments. They can withstand temperature fluctuations, mechanical stresses, and vibrations without compromising their performance, ensuring the smooth operation of electronic systems in aerospace applications.

Another advantage of using rigid-flex printed circuits in the aerospace industry is their lightweight and compact design.Space is a premium in aircraft and spacecraft, and every ounce of weight matters. Rigid-flex printed circuits are lightweight and can be designed to fit into tight spaces, making them ideal for use in compact electronic systems. Their flexible design allows them to be bent and folded to fit the shape of the aircraft or spacecraft, maximizing the use of available space and reducing the overall weight of the electronic system.

Furthermore, rigid-flex printed circuits offer improved signal integrity and reliability compared to traditional wiring harnesses.

The integrated design of rigid-flex printed circuits reduces the number of interconnects and solder joints, minimizing signal loss and improving signal integrity. This results in better performance and reliability of electronic systems in aerospace applications. Additionally, the flexible nature of rigid-flex printed circuits reduces the risk of mechanical failures and short circuits, further enhancing the reliability of electronic systems in aerospace applications.

In addition to their durability, lightweight design, and improved signal integrity, rigid-flex printed circuits offer cost savings in the aerospace industry.

The integrated design of rigid-flex printed circuits reduces the need for additional components, connectors, and wiring, resulting in lower material and labor costs. The compact design of rigid-flex printed circuits also reduces the overall size and weight of electronic systems, leading to fuel savings in aircraft and spacecraft. Furthermore, the reliability and longevity of rigid-flex printed circuits reduce maintenance and repair costs, making them a cost-effective solution for electronic systems in aerospace applications.

Overall, the benefits of using rigid-flex printed circuits in the aerospace industry are numerous. From their ability to withstand harsh environmental conditions to their lightweight and compact design, rigid-flex printed circuits offer a reliable and cost-effective solution for electronic systems in aircraft, spacecraft, and satellites. Their improved signal integrity and reliability make them an ideal choice for critical applications in the aerospace industry. As technology continues to advance, rigid-flex printed circuits will play an increasingly important role in shaping the future of electronic systems in aerospace applications.