Benefits of Using Rigid-Flex Printed Circuits in Aerospace Industry

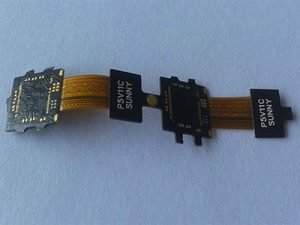

Rigid-flex printed circuits have become an essential component in various industries due to their flexibility, durability, and reliability.

One industry that has greatly benefited from the use of rigid-flex printed circuits is the aerospace industry.These circuits have revolutionized the way electronic systems are designed and integrated into aircraft, spacecraft, and satellites.

One of the key benefits of using rigid-flex printed circuits in the aerospace industry is their ability to withstand harsh environmental conditions.

Aircraft and spacecraft are exposed to extreme temperatures, vibrations, and pressures during flight. Rigid-flex printed circuits are designed to be highly durable and resistant to these conditions, ensuring that electronic systems function reliably throughout the duration of a mission.

In addition to their durability, rigid-flex printed circuits offer significant space-saving advantages.In the aerospace industry, where every inch of space is precious, the compact design of rigid-flex circuits allows for more efficient use of space within electronic systems. This is particularly important in spacecraft and satellites, where weight and size constraints are critical factors in mission success.

Furthermore, rigid-flex printed circuits provide enhanced reliability compared to traditional wiring harnesses. The integrated design of rigid-flex circuits reduces the number of interconnect points, minimizing the risk of signal interference, short circuits, and other common issues that can arise with traditional wiring systems. This increased reliability is crucial in the aerospace industry, where system failures can have catastrophic consequences.

Another key advantage of using rigid-flex printed circuits in the aerospace industry is their ability to support complex and high-speed electronic systems. Modern aircraft and spacecraft are equipped with advanced avionics, communication systems, and sensors that require fast and precise data processing. Rigid-flex circuits are capable of supporting high-speed signals and complex routing configurations, making them ideal for these demanding applications.

The versatility of rigid-flex printed circuits also makes them well-suited for a wide range of aerospace applications. Whether used in flight control systems, navigation systems, communication systems, or power distribution systems, rigid-flex circuits can be customized to meet the specific requirements of each application. This flexibility allows aerospace engineers to design innovative and efficient electronic systems that are tailored to the unique needs of each mission.

Overall, the benefits of using rigid-flex printed circuits in the aerospace industry are clear. From their durability and reliability to their space-saving advantages and support for complex electronic systems, rigid-flex circuits have become an indispensable technology in the design and integration of electronic systems in aircraft, spacecraft, and satellites. As the aerospace industry continues to push the boundaries of technology and innovation, rigid-flex printed circuits will play a crucial role in enabling the next generation of aerospace systems to reach new heights of performance and reliability.