The Manufacturing Process of Rigid-Flex Printed Circuits

Rigid-flex printed circuits are a crucial component in many electronic devices, providing a flexible and durable solution for connecting various components.

The manufacturing process of rigid-flex printed circuits is a complex and intricate one, involving multiple steps and precise techniques to ensure the final product meets the required specifications.

The first step in the manufacturing process of rigid-flex printed circuits is the design phase. Engineers work closely with designers to create a layout that meets the specific requirements of the device. This involves determining the size and shape of the circuit, as well as the placement of components and connectors. Once the design is finalized, it is sent to the fabrication facility for production.

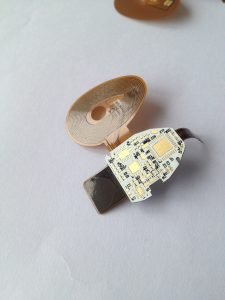

The fabrication process begins with the creation of the rigid portion of the circuit. This involves laminating layers of copper and substrate material together to create a rigid base. The layers are then etched to create the desired circuit pattern, with holes drilled for component placement. Once the rigid portion is complete, the flexible portion is added.

The flexible portion of the circuit is created using a similar process, but with flexible substrate material instead of rigid. The flexible portion is then attached to the rigid portion using adhesive or other bonding techniques. This creates a seamless transition between the two sections, allowing for flexibility while maintaining durability.

Once the circuit is fully assembled, it undergoes testing to ensure it meets the required specifications. This involves checking for continuity, resistance, and other electrical properties to ensure the circuit functions properly. Any defects or issues are addressed before the final product is shipped to the customer.

Overall, the manufacturing process of rigid-flex printed circuits is a complex and precise one, requiring careful attention to detail and skilled technicians to ensure the final product meets the required specifications. From design to fabrication to testing, each step plays a crucial role in creating a high-quality circuit that can withstand the rigors of everyday use.

In conclusion, rigid-flex printed circuits are an essential component in many electronic devices, providing a flexible and durable solution for connecting various components. The manufacturing process of rigid-flex printed circuits is a complex and intricate one, involving multiple steps and precise techniques to ensure the final product meets the required specifications. From design to fabrication to testing, each step plays a crucial role in creating a high-quality circuit that can withstand the rigors of everyday use.