Benefits of Next-Gen Rigid-Flexible PCB Solutions

In the world of electronics manufacturing, the demand for smaller, lighter, and more reliable products is constantly increasing.

As a result, designers and engineers are always on the lookout for innovative solutions that can help them meet these requirements.

One such solution that has been gaining popularity in recent years is the use of next-generation rigid-flexible PCBs.

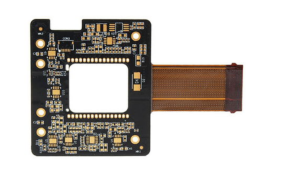

Rigid-flex PCBs combine the best of both worlds by incorporating rigid and flexible circuitry into a single board.

This allows for greater design flexibility, reduced assembly time, and improved reliability compared to traditional PCBs.

In this article, we will explore some of the key benefits of next-gen rigid-flexible PCB solutions.

One of the main advantages of using rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, designers can create more compact and lightweight products without sacrificing functionality.

This is especially important in industries such as aerospace, automotive, and medical devices, where space and weight constraints are critical considerations.

Another benefit of rigid-flex PCBs is their improved reliability. Traditional PCBs are prone to failure due to factors such as vibration, shock, and thermal stress. Rigid-flex PCBs, on the other hand, are more resistant to these environmental factors, making them ideal for applications that require high reliability and durability. This can result in lower maintenance costs and longer product lifespans, ultimately leading to greater customer satisfaction.

In addition to their size, weight, and reliability advantages, rigid-flex PCBs also offer greater design flexibility.

Designers can create complex, three-dimensional shapes that would be impossible with traditional PCBs, allowing for more creative and innovative product designs. This flexibility can also lead to cost savings by reducing the number of components and assembly steps required for a given design.

Furthermore, rigid-flex PCBs can help streamline the manufacturing process by reducing the number of interconnects and solder joints required.

This can lead to faster assembly times, lower labor costs, and improved overall product quality.

Additionally, the use of rigid-flex PCBs can simplify the testing and debugging process, as there are fewer points of failure compared to traditional PCBs.

Overall, the benefits of next-gen rigid-flexible PCB solutions are clear.

From reduced size and weight to improved reliability and design flexibility, these innovative boards offer a wide range of advantages for designers and engineers looking to create cutting-edge electronic products.By incorporating rigid-flex PCBs into their designs, manufacturers can stay ahead of the competition and meet the ever-increasing demands of the market.

In conclusion, next-gen rigid-flexible PCB solutions are revolutionizing the electronics industry by offering a host of benefits that traditional PCBs simply cannot match. With their smaller size, lighter weight, improved reliability, and greater design flexibility, rigid-flex PCBs are quickly becoming the go-to choice for designers and engineers looking to push the boundaries of what is possible in electronic product design.As technology continues to evolve, it is clear that rigid-flex PCBs will play a key role in shaping the future of electronics manufacturing.