Benefits of Using Bespoke Rigid-Flexible PCBs in Medical Devices

Bespoke rigid-flexible PCBs are becoming increasingly popular in the medical device industry due to their numerous benefits and applications.

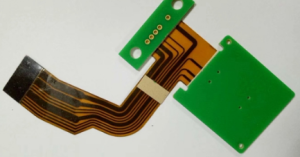

These specialized circuit boards offer a unique combination of rigid and flexible components, allowing for greater design flexibility and reliability in medical devices. In this article, we will explore the benefits of using bespoke rigid-flexible PCBs in medical devices and discuss some of the key applications where these advanced circuit boards are making a difference.

One of the primary benefits of using bespoke rigid-flexible PCBs in medical devices is their ability to reduce the overall size and weight of the device.

By combining rigid and flexible components into a single circuit board, designers can create more compact and lightweight devices that are easier to handle and transport. This is particularly important in medical devices where space is limited, such as implantable devices or wearable sensors.

In addition to their compact size, bespoke rigid-flexible PCBs also offer improved reliability and durability compared to traditional rigid PCBs.

The flexible components of these circuit boards help to absorb shock and vibration, reducing the risk of damage to the device during use.

This is especially important in medical devices that are subject to frequent movement or handling, such as wearable monitors or surgical tools.

Another key benefit of using bespoke rigid-flexible PCBs in medical devices is their ability to support complex and intricate designs.

The flexible components of these circuit boards can be bent or folded to fit into tight spaces or conform to irregular shapes, allowing for greater design flexibility and customization. This is particularly useful in medical devices where the circuit board needs to be integrated into a specific form factor or shape, such as in pacemakers or catheters.

Furthermore, bespoke rigid-flexible PCBs offer improved signal integrity and performance compared to traditional rigid PCBs.

The flexible components of these circuit boards help to reduce signal interference and crosstalk, resulting in cleaner and more reliable signal transmission. This is crucial in medical devices where accurate and timely data transmission is essential for proper device function and patient safety.

In terms of applications, bespoke rigid-flexible PCBs are being used in a wide range of medical devices, including implantable devices, wearable sensors, diagnostic equipment, and surgical tools. In implantable devices, these circuit boards are used to create compact and lightweight devices that can be easily implanted into the body without causing discomfort or interference. In wearable sensors, bespoke rigid-flexible PCBs are used to create flexible and conformable devices that can be worn comfortably on the body for extended periods of time.

In diagnostic equipment, these circuit boards are used to create high-performance devices that can accurately and reliably measure and analyze biological signals. In surgical tools, bespoke rigid-flexible PCBs are used to create precise and reliable devices that can assist surgeons in performing complex procedures with greater accuracy and efficiency.

Overall, bespoke rigid-flexible PCBs offer numerous benefits for medical device designers and manufacturers, including reduced size and weight, improved reliability and durability, greater design flexibility, and enhanced signal integrity and performance. These advanced circuit boards are revolutionizing the medical device industry and are helping to create more innovative and effective devices that improve patient care and outcomes.