Benefits of Using Rigid-Flexible PCBs

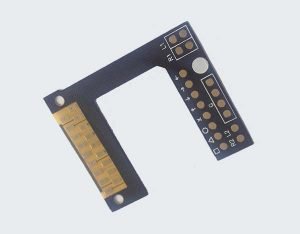

Printed circuit boards (PCBs) are an essential component in the world of electronics. They provide a platform for connecting various electronic components and ensuring the smooth operation of electronic devices. Over the years, PCB technology has evolved, leading to the development of rigid-flex PCBs.

These innovative PCBs combine the benefits of both rigid and flexible PCBs, offering a unique solution for a wide range of applications.

One of the key benefits of using rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible sections in a single board, designers can create compact and lightweight PCBs that can fit into tight spaces and conform to the shape of the device. This is particularly useful in applications where space is limited, such as in wearable devices, medical implants, and aerospace systems.

In addition to their compact size, rigid-flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The flexible sections of the board are designed to withstand bending and flexing without compromising the integrity of the circuitry.

This makes rigid-flex PCBs ideal for applications that require frequent movement or exposure to harsh environmental conditions.

For example, in automotive applications, rigid-flex PCBs can withstand the vibrations and temperature fluctuations experienced in a vehicle’s engine compartment.

Another benefit of using rigid-flex PCBs is their enhanced signal integrity. The combination of rigid and flexible sections allows designers to optimize the layout of the board to minimize signal interference and crosstalk. This results in improved signal quality and reduced electromagnetic interference, leading to better overall performance of the electronic device. In high-speed applications, such as data communication systems and high-frequency RF devices, rigid-flex PCBs are the preferred choice for ensuring reliable signal transmission.

Furthermore, rigid-flex PCBs offer cost savings in terms of assembly and maintenance. By integrating multiple PCBs into a single rigid-flex board, designers can reduce the number of interconnects and solder joints, simplifying the assembly process and minimizing the risk of connection failures. Additionally, the durability of rigid-flex PCBs means that they require less frequent maintenance and replacement, leading to long-term cost savings for manufacturers and end-users.

Overall, the benefits of using rigid-flex PCBs make them a versatile and cost-effective solution for a wide range of electronic applications.

Whether it’s reducing size and weight, improving reliability and signal integrity, or saving on assembly and maintenance costs, rigid-flex PCBs offer a host of advantages that make them an attractive choice for designers and manufacturers alike.

In conclusion, understanding the basics of rigid-flex PCBs is essential for anyone involved in the design and manufacturing of electronic devices.

By harnessing the unique benefits of rigid-flex PCBs, designers can create innovative and reliable products that meet the demands of today’s fast-paced electronics industry. With their compact size, enhanced reliability, improved signal integrity, and cost savings, rigid-flex PCBs are sure to play a key role in shaping the future of electronic technology.