Benefits of Using Rigid-Flexible PCBs in Electronic Design

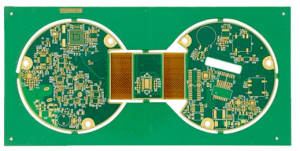

Rigid-flex PCBs, or rigid-flexible printed circuit boards, have become increasingly popular in electronic design due to their numerous benefits.

These innovative PCBs combine the advantages of both rigid and flexible PCBs, offering designers more flexibility in creating complex electronic devices.

In this article, we will explore the design considerations for rigid-flex PCBs and discuss why they are a preferred choice for many electronic applications.

One of the key benefits of using rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible sections in a single board, designers can create compact and lightweight products that are ideal for applications where space is limited. This can be particularly advantageous in industries such as aerospace, medical devices, and consumer electronics, where size and weight constraints are critical considerations.

Another advantage of rigid-flex PCBs is their improved reliability and durability.Traditional PCBs are prone to mechanical stress and vibration, which can lead to solder joint failures and other reliability issues. Rigid-flex PCBs, on the other hand, are more resistant to these types of stresses due to their flexible sections, which can absorb and distribute mechanical forces more effectively. This results in a more robust and reliable electronic device that is less likely to fail under harsh operating conditions.

In addition to their compact size and improved reliability, rigid-flex PCBs also offer greater design flexibility.

Designers can create complex three-dimensional shapes and configurations that would be difficult or impossible to achieve with traditional PCBs.

This opens up new possibilities for innovative product designs and allows for more efficient use of space within the device. Furthermore, the use of flexible sections in the PCB can simplify the assembly process and reduce the number of interconnects, leading to lower manufacturing costs and faster time to market.

When designing a rigid-flex PCB, there are several key considerations that designers must take into account.One of the most important factors is the selection of materials. The choice of materials will depend on the specific requirements of the application, including factors such as temperature range, mechanical stress, and signal integrity. It is essential to select materials that can withstand the operating conditions of the device while maintaining good electrical performance.

Another important consideration in rigid-flex PCB design is the placement of components and routing of traces.

Designers must carefully plan the layout of the board to ensure that components are placed in optimal locations and that signal paths are optimized for performance. This may involve using advanced design tools and techniques to minimize signal interference and ensure signal integrity throughout the board.

In conclusion, rigid-flex PCBs offer numerous benefits for electronic design, including reduced size and weight, improved reliability, and greater design flexibility. By carefully considering materials, component placement, and trace routing, designers can create high-performance rigid-flex PCBs that meet the requirements of even the most demanding applications. With their unique combination of rigid and flexible elements, rigid-flex PCBs are sure to play an increasingly important role in the future of electronic design.