Benefits of Using Rigid-Flexible PCBs in Manufacturing Processes

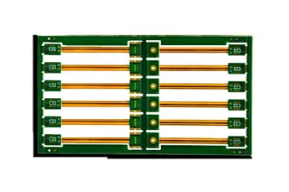

Rigid-flex PCBs, or rigid-flexible printed circuit boards, are a type of PCB that combines the benefits of both rigid and flexible PCBs.

These boards are made up of both rigid and flexible materials, allowing for increased design flexibility and reliability in a variety of applications.

The manufacturing process of rigid-flex PCBs is complex and requires careful attention to detail to ensure the final product meets the required specifications.

The manufacturing process of rigid-flex PCBs begins with the design phase, where engineers work closely with designers to create a layout that meets the specific requirements of the application. Once the design is finalized, the next step is to create the rigid and flexible layers that will make up the PCB.

This is done by laminating together layers of copper and substrate material, which are then etched to create the desired circuit pattern.

One of the key benefits of using rigid-flex PCBs in manufacturing processes is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible materials, designers can create PCBs that can be folded or bent to fit into tight spaces, allowing for more compact and lightweight designs. This is particularly useful in applications where space is limited, such as in medical devices or aerospace equipment.

Another benefit of using rigid-flex PCBs is their increased reliability and durability. The combination of rigid and flexible materials helps to reduce the risk of mechanical failure, as the flexible portions of the PCB can absorb and distribute stress more effectively than traditional rigid PCBs.

This makes rigid-flex PCBs ideal for applications where the board may be subject to bending or vibration, such as in automotive or industrial equipment.

In addition to their compact size and increased reliability, rigid-flex PCBs also offer improved signal integrity and reduced electromagnetic interference.

The use of flexible materials in the PCB design helps to minimize signal loss and crosstalk, resulting in better overall performance and reliability.

This is particularly important in high-speed applications, where signal integrity is critical to the operation of the device.

The manufacturing process of rigid-flex PCBs also allows for greater design flexibility and customization. Designers can create complex layouts that would be difficult or impossible to achieve with traditional rigid PCBs, allowing for more innovative and efficient designs. This flexibility is particularly useful in applications where space is limited or where the PCB needs to conform to a specific shape or size.

Overall, the manufacturing process of rigid-flex PCBs offers a number of benefits for manufacturers looking to create compact, reliable, and high-performance electronic devices. By combining the benefits of rigid and flexible materials, designers can create PCBs that meet the specific requirements of their application while also reducing size, weight, and cost. With their improved reliability, signal integrity, and design flexibility, rigid-flex PCBs are an ideal choice for a wide range of manufacturing processes.