Importance of Testing and Quality Control in Rigid-Flexible PCB Manufacturing

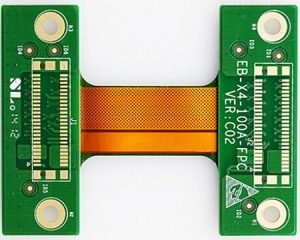

In the world of electronics manufacturing, ensuring the quality and reliability of printed circuit boards (PCBs) is of utmost importance. This is especially true for rigid-flexible PCBs, which combine the benefits of both rigid and flexible PCBs in one design. These boards are commonly used in applications where space constraints and complex geometries are a concern, such as in medical devices, aerospace systems, and consumer electronics.

Testing and quality control play a crucial role in the manufacturing process of rigid-flexible PCBs. By conducting thorough testing at various stages of production, manufacturers can identify and rectify any defects or issues that may arise, ensuring that the final product meets the required specifications and standards.

One of the key reasons why testing and quality control are essential in rigid-flexible PCB manufacturing is to ensure the reliability and durability of the boards. Rigid-flexible PCBs are often subjected to harsh environmental conditions, such as temperature fluctuations, moisture, and mechanical stress. Without proper testing, these boards may fail prematurely, leading to costly repairs and replacements.

To address this issue, manufacturers employ a variety of testing methods to assess the performance and reliability of rigid-flexible PCBs. These include electrical testing, thermal testing, mechanical testing, and environmental testing. Electrical testing, for example, involves checking the conductivity and insulation properties of the board to ensure that it functions correctly. Thermal testing, on the other hand, evaluates the board’s ability to withstand temperature variations without compromising its performance.

In addition to testing, quality control measures are also implemented throughout the manufacturing process to maintain consistency and reliability. This includes inspecting raw materials, monitoring production processes, and conducting final inspections before the boards are shipped to customers. By adhering to strict quality control standards, manufacturers can minimize the risk of defects and ensure that each board meets the required specifications.

Another important aspect of testing and quality control in rigid-flexible PCB manufacturing is compliance with industry standards and regulations. In many industries, such as aerospace and medical devices, strict guidelines are in place to ensure the safety and reliability of electronic components. By conducting thorough testing and adhering to these standards, manufacturers can demonstrate that their products meet the necessary requirements and are safe for use in critical applications.

Furthermore, testing and quality control also play a role in reducing the overall cost of production. By identifying and addressing defects early in the manufacturing process, manufacturers can avoid costly rework and scrap, ultimately saving time and resources. Additionally, by producing high-quality boards that meet customer expectations, manufacturers can build a reputation for reliability and excellence, leading to increased customer satisfaction and loyalty.

In conclusion, testing and quality control are essential components of rigid-flexible PCB manufacturing. By conducting thorough testing, implementing strict quality control measures, and adhering to industry standards, manufacturers can ensure the reliability, durability, and safety of their products. Ultimately, investing in testing and quality control not only benefits manufacturers but also customers who rely on high-quality electronic components for their applications.