Integration of 5G Technology in Rigid-Flexible PCBs

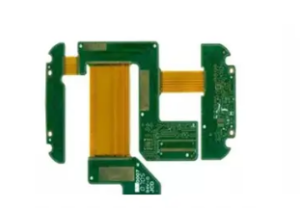

The integration of 5G technology in rigid-flexible PCBs is a significant trend that is shaping the future of electronic devices. As the demand for faster and more reliable communication continues to grow, manufacturers are looking for ways to incorporate 5G capabilities into their products. Rigid-flex PCBs offer a unique solution to this challenge by combining the benefits of both rigid and flexible circuit boards.

One of the key advantages of using rigid-flex PCBs for 5G technology is their ability to support high-frequency signals. 5G networks operate at much higher frequencies than previous generations, which can pose challenges for traditional PCB designs. Rigid-flex PCBs are able to provide the necessary signal integrity and impedance control to ensure reliable communication in 5G devices.

Another benefit of using rigid-flex PCBs for 5G technology is their compact and lightweight design. 5G devices are expected to be smaller and more portable than ever before, and rigid-flex PCBs allow manufacturers to create more compact and lightweight products. This is especially important for applications such as wearable technology and IoT devices, where space is limited.

In addition to their technical advantages, rigid-flex PCBs also offer cost savings for manufacturers. By combining multiple PCBs into a single design, manufacturers can reduce the overall cost of production and assembly. This can help to make 5G devices more affordable for consumers, driving adoption of the technology.

As 5G technology continues to evolve, so too will the design and capabilities of rigid-flex PCBs. Manufacturers are constantly looking for ways to improve the performance and reliability of these boards to meet the demands of 5G devices. This includes advancements in materials, manufacturing processes, and design techniques.

One area of focus for future developments in rigid-flex PCB technology is the use of advanced materials. New materials with improved thermal and electrical properties are being developed to enhance the performance of rigid-flex PCBs in 5G devices. These materials can help to reduce signal loss, improve signal integrity, and increase the overall reliability of the PCB.

Manufacturing processes are also evolving to meet the demands of 5G technology. Advances in automation and robotics are helping to streamline the production of rigid-flex PCBs, making them more cost-effective and efficient. This allows manufacturers to produce high-quality boards at a faster pace, meeting the growing demand for 5G devices.

Design techniques are another area of focus for future trends in rigid-flex PCB technology. Engineers are exploring new ways to optimize the layout and routing of PCBs to improve signal integrity and reduce interference. This includes the use of advanced simulation tools and modeling techniques to predict and analyze the performance of rigid-flex PCBs in 5G devices.

In conclusion, the integration of 5G technology in rigid-flex PCBs is a key trend that is shaping the future of electronic devices. By combining the benefits of both rigid and flexible circuit boards, manufacturers are able to create high-performance, compact, and cost-effective solutions for 5G devices. As technology continues to evolve, so too will the design and capabilities of rigid-flex PCBs, ensuring that they remain at the forefront of innovation in the electronics industry.