Benefits of Using Rigid-Flexible PCBs in Wearable Technology

In the rapidly evolving world of technology, wearable devices have become increasingly popular for their convenience and functionality. From fitness trackers to smartwatches, these devices have revolutionized the way we interact with technology on a daily basis. One key component that enables the seamless integration of technology into wearable devices is the use of rigid-flexible printed circuit boards (PCBs).

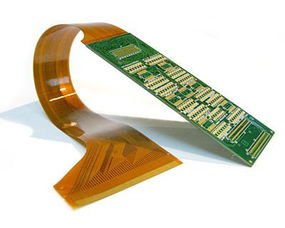

Rigid-flex PCBs are a hybrid of traditional rigid PCBs and flexible PCBs, offering the best of both worlds in terms of durability and flexibility. These boards are designed to be both rigid and flexible, allowing them to bend and twist without breaking. This unique combination of properties makes rigid-flex PCBs ideal for use in wearable technology, where space is limited and flexibility is essential.

One of the key benefits of using rigid-flex PCBs in wearable technology is their ability to reduce the overall size and weight of the device. Traditional rigid PCBs are bulky and inflexible, making them unsuitable for use in small, lightweight devices. By using rigid-flex PCBs, manufacturers can design devices that are thinner and more lightweight, without sacrificing performance or durability.

Another advantage of using rigid-flex PCBs in wearable technology is their ability to withstand the rigors of everyday use. Wearable devices are often subjected to bending, twisting, and other forms of physical stress, which can cause traditional PCBs to fail. Rigid-flex PCBs, on the other hand, are designed to be more durable and resilient, making them ideal for use in devices that are worn on the body.

In addition to their durability and flexibility, rigid-flex PCBs also offer improved signal integrity and reliability. The flexible portions of the board allow for better routing of signals, reducing the risk of interference and signal loss. This results in improved performance and reliability, making rigid-flex PCBs an ideal choice for use in wearable technology.

Furthermore, rigid-flex PCBs are also more cost-effective in the long run. While the initial cost of manufacturing rigid-flex PCBs may be higher than traditional PCBs, the durability and reliability of these boards can help to reduce maintenance and replacement costs over time. This makes rigid-flex PCBs a smart investment for manufacturers looking to create high-quality, long-lasting wearable devices.

Overall, the use of rigid-flex PCBs in wearable technology offers a wide range of benefits, from improved durability and flexibility to enhanced signal integrity and reliability. These boards enable manufacturers to create smaller, lighter, and more reliable devices that can withstand the rigors of everyday use. As wearable technology continues to evolve and expand, rigid-flex PCBs will play an increasingly important role in shaping the future of this exciting industry.