Advantages of Using Rigid-Flexible PCBs in Aerospace and Military Applications

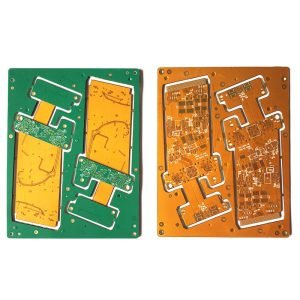

Rigid-flex PCBs, or rigid-flexible printed circuit boards, have become increasingly popular in aerospace and military applications due to their unique design and numerous advantages. These specialized PCBs combine the benefits of both rigid and flexible circuit boards, offering a high level of reliability, durability, and flexibility that make them ideal for use in harsh environments and demanding applications.

One of the key advantages of using rigid-flex PCBs in aerospace and military applications is their ability to withstand extreme temperatures, vibrations, and mechanical stress. The rigid sections of the PCB provide stability and support for components, while the flexible sections allow for bending and folding without compromising the integrity of the circuit. This flexibility is crucial in applications where space is limited or where the PCB needs to conform to a specific shape or design.

In addition to their durability and flexibility, rigid-flex PCBs also offer improved signal integrity and reduced electromagnetic interference (EMI). The rigid sections of the PCB provide a solid ground plane and shielding for sensitive components, while the flexible sections allow for controlled impedance routing and reduced signal loss. This results in better performance and reliability, especially in high-speed and high-frequency applications common in aerospace and military systems.

Another advantage of using rigid-flex PCBs is their compact size and weight savings. By combining multiple rigid and flexible layers into a single PCB, designers can reduce the overall size and weight of the circuit board, making it ideal for applications where space and weight are critical factors. This compact design also reduces the need for additional connectors and cables, simplifying the overall system design and assembly process.

Furthermore, rigid-flex PCBs offer improved reliability and longevity compared to traditional PCBs. The elimination of connectors and cables reduces the risk of mechanical failure and signal degradation, while the use of high-quality materials and manufacturing processes ensures a high level of performance and durability. This reliability is crucial in aerospace and military applications where system failure can have serious consequences.

Overall, the advantages of using rigid-flex PCBs in aerospace and military applications make them an attractive choice for designers and engineers looking to improve the performance, reliability, and durability of their systems. From their ability to withstand extreme conditions to their compact size and weight savings, rigid-flex PCBs offer a range of benefits that make them well-suited for use in demanding environments.

In conclusion, rigid-flex PCBs are an innovative and versatile solution for aerospace and military applications, offering a unique combination of durability, flexibility, and performance. With their ability to withstand extreme conditions, reduce signal loss, and save space and weight, rigid-flex PCBs are an ideal choice for applications where reliability and performance are paramount. As technology continues to advance, rigid-flex PCBs will likely play an increasingly important role in the development of next-generation aerospace and military systems.