Benefits of Using Rigid-Flex Electric PCB Design

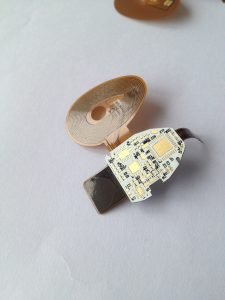

Rigid-flex electric PCB design is a cutting-edge technology that combines the benefits of rigid and flexible PCBs into one innovative solution.

This design allows for increased flexibility and durability, making it ideal for a wide range of applications in various industries.

There are several key benefits to using rigid-flex electric PCB design, which we will explore in this article.

One of the primary advantages of rigid-flex electric PCB design is its ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible PCBs into a single design, manufacturers can create more compact and lightweight products without sacrificing performance. This is particularly beneficial for portable devices such as smartphones, tablets, and wearable technology, where space and weight are critical factors.

In addition to reducing size and weight, rigid-flex electric PCB design also offers improved reliability and durability.

Traditional PCBs are prone to damage from bending, twisting, and vibration, which can lead to electrical failures and malfunctions. Rigid-flex PCBs,

on the other hand, are designed to withstand these types of stresses, making them more reliable and long-lasting. This increased durability is especially important for applications in harsh environments or high-impact settings.

Another key benefit of rigid-flex electric PCB design is its ability to simplify assembly and reduce production costs.

By combining multiple PCBs into a single design, manufacturers can streamline the assembly process and eliminate the need for complex interconnects

and connectors. This not only reduces the risk of assembly errors but also lowers production costs by reducing the number of components and materials required. Additionally, the simplified design of rigid-flex PCBs can lead to faster production times and increased efficiency.

Furthermore, rigid-flex electric PCB design offers greater design flexibility and customization options compared to traditional PCBs.

Manufacturers can create complex and intricate designs that would be difficult or impossible to achieve with rigid or flexible PCBs alone.

This allows for more creative and innovative product designs, as well as the ability to tailor PCB layouts to specific application requirements.

Whether it’s creating a custom shape or integrating multiple components into a single board, rigid-flex PCB design offers endless possibilities for customization.

Overall, the benefits of using rigid-flex electric PCB design are clear. From reducing size and weight to improving reliability and durability, this innovative technology offers a wide range of advantages for manufacturers and designers alike. By taking advantage of the flexibility, durability, and customization options that rigid-flex PCBs provide, companies can create more compact, reliable, and cost-effective electronic devices that meet the demands of today’s fast-paced market.