Benefits of Using Rigid-Flex Electric PCB Prototype in Electronic Devices

In the world of electronic devices, the demand for smaller, lighter, and more flexible components is constantly growing.

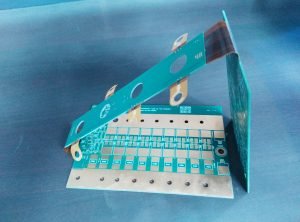

This is where rigid-flex electric PCB prototypes come into play. These innovative circuit boards offer a unique combination of rigid and flexible materials, allowing for greater design flexibility and improved performance in a wide range of applications.

One of the key benefits of using rigid-flex electric PCB prototypes is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible materials in a single board, designers can create compact and lightweight circuits that can be easily integrated into even the smallest of devices. This is particularly important in industries such as aerospace, medical devices, and wearable technology, where space and weight constraints are critical considerations.

Another advantage of rigid-flex electric PCB prototypes is their enhanced reliability and durability.

Traditional rigid PCBs are prone to failure due to mechanical stress, especially in applications where the board is subject to bending or flexing.

Rigid-flex boards, on the other hand, are designed to withstand these stresses, making them ideal for applications where reliability is paramount.

This increased durability can result in longer product lifespans and reduced maintenance costs, making rigid-flex electric PCB prototypes a cost-effective solution for many electronic devices.

In addition to their size, weight, and reliability benefits, rigid-flex electric PCB prototypes also offer improved signal integrity and performance.

The flexible portions of the board allow for tighter routing of traces, reducing signal interference and improving overall signal quality.

This can result in faster data transfer speeds, reduced electromagnetic interference, and improved overall performance of the electronic device.

In applications where signal integrity is critical, such as high-speed data transmission or RF communication, rigid-flex electric PCB prototypes offer a significant advantage over traditional rigid boards.

Furthermore, rigid-flex electric PCB prototypes can also simplify the assembly process and reduce manufacturing costs.

By combining multiple boards into a single unit, designers can eliminate the need for connectors and cables, reducing the number of components and potential points of failure. This can result in faster assembly times, lower labor costs, and reduced material waste, making rigid-flex electric PCB prototypes a cost-effective solution for manufacturers looking to streamline their production processes.

Overall, the benefits of using rigid-flex electric PCB prototypes in electronic devices are clear.

From their compact size and lightweight design to their enhanced reliability and performance, rigid-flex boards offer a range of advantages that make them an attractive option for a wide range of applications. Whether you’re designing a cutting-edge wearable device or a high-performance aerospace system, rigid-flex electric PCB prototypes can help you achieve your design goals and bring your innovative ideas to life.