Benefits of Using Rigid-Flex Electric PCBs in Manufacturing Processes

Rigid-flex electric PCBs have become increasingly popular in the manufacturing industry due to their numerous benefits.

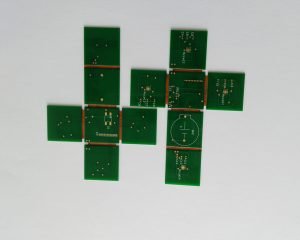

These innovative circuit boards combine the flexibility of flexible PCBs with the durability of rigid PCBs, making them ideal for a wide range of applications.

In this article, we will explore the advantages of using rigid-flex electric PCBs in manufacturing processes.

One of the key benefits of rigid-flex electric PCBs is their space-saving design.

By combining the functionality of multiple PCBs into a single unit, manufacturers can reduce the overall size and weight of their electronic devices.

This is particularly important in industries where space is limited, such as aerospace and medical devices.

Additionally, the compact design of rigid-flex electric PCBs can help streamline the manufacturing process, leading to cost savings and improved efficiency.

Another advantage of rigid-flex electric PCBs is their enhanced reliability.

Traditional PCBs are prone to failure due to factors such as vibration, temperature fluctuations, and mechanical stress.

Rigid-flex electric PCBs, on the other hand, are more resistant to these environmental factors, making them ideal for use in harsh operating conditions.

This increased reliability can help manufacturers reduce downtime and maintenance costs, leading to improved overall performance.

In addition to their space-saving design and enhanced reliability, rigid-flex electric PCBs offer greater design flexibility.

Manufacturers can create custom layouts and shapes to fit the specific requirements of their electronic devices.

This flexibility allows for more efficient use of space and can help optimize the performance of the final product.

Furthermore, the ability to integrate multiple functions into a single PCB can simplify the overall design process, reducing development time and costs.

Rigid-flex electric PCBs also offer improved signal integrity.By reducing the number of interconnects and eliminating the need for connectors, manufacturers can minimize signal loss and interference.This can lead to better overall performance and reliability of the electronic device.Additionally, the use of high-quality materials and advanced manufacturing techniques can further enhance signal integrity, ensuring consistent and reliable operation.

Overall, the benefits of using rigid-flex electric PCBs in manufacturing processes are clear.

From space-saving design and enhanced reliability to greater design flexibility and improved signal integrity, these innovative circuit boards offer a wide range of advantages for manufacturers. By incorporating rigid-flex electric PCBs into their electronic devices, manufacturers can improve performance, reduce costs, and stay ahead of the competition in today’s fast-paced market.

In conclusion, rigid-flex electric PCBs are a valuable tool for manufacturers looking to optimize their manufacturing processes.

With their space-saving design, enhanced reliability, greater design flexibility, and improved signal integrity, these innovative circuit boards offer a wide range of benefits that can help manufacturers stay competitive in today’s rapidly evolving industry. By incorporating rigid-flex electric PCBs into their electronic devices, manufacturers can achieve greater efficiency, reliability, and performance, ultimately leading to a more successful and profitable manufacturing process.