Benefits of Rigid-Flex PCB Assembly

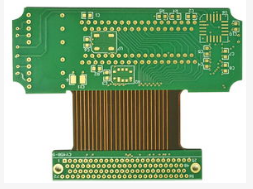

Rigid-flex PCB assembly is a cutting-edge technology that is revolutionizing the electronics industry.

By combining the benefits of rigid and flexible PCBs, this innovative approach offers a wide range of advantages that traditional PCBs simply cannot match. In this article, we will explore the benefits of rigid-flex PCB assembly and how it is pushing the boundaries of technology.

One of the key benefits of rigid-flex PCB assembly is its ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, rigid-flex PCBs allow for more compact and lightweight designs.

This is particularly important in industries such as aerospace and medical devices, where space and weight constraints are critical.

In addition to size and weight savings, rigid-flex PCB assembly also offers improved reliability.

Traditional PCBs are prone to failure due to the constant movement and stress placed on the board. Rigid-flex PCBs, on the other hand, are designed to withstand bending and flexing without compromising performance. This makes them ideal for applications that require frequent movement or exposure to harsh environments.

Another benefit of rigid-flex PCB assembly is its cost-effectiveness.

While the initial investment may be higher than traditional PCBs, the long-term savings are significant.

Rigid-flex PCBs require fewer components and less assembly time, resulting in lower production costs.

Additionally, the increased reliability of rigid-flex PCBs reduces the need for costly repairs and replacements, further lowering overall costs.

Furthermore, rigid-flex PCB assembly offers greater design flexibility.

Traditional PCBs are limited by their rigid nature, making it difficult to create complex shapes or fit into tight spaces.

Rigid-flex PCBs, on the other hand, can be molded into virtually any shape, allowing for more creative and innovative designs.

This flexibility opens up a world of possibilities for engineers and designers, enabling them to create products that were previously thought impossible.

In addition to these benefits, rigid-flex PCB assembly also offers improved signal integrity.

Traditional PCBs are prone to signal interference and crosstalk, which can degrade performance and reliability.

Rigid-flex PCBs, with their integrated design and reduced number of connectors, minimize signal loss and improve overall signal quality. This results in faster data transmission speeds and more reliable performance, making rigid-flex PCBs ideal for high-speed and high-frequency applications.

Overall, the benefits of rigid-flex PCB assembly are clear.

From size and weight savings to improved reliability and design flexibility, this innovative technology is pushing the boundaries of what is possible in the electronics industry.

As demand for smaller, lighter, and more reliable electronic devices continues to grow, rigid-flex PCB assembly will play an increasingly important role in shaping the future of technology.

With its numerous advantages and endless possibilities, rigid-flex PCB assembly is truly a game-changer in the world of electronics.