Benefits of Rigid-Flex PCB Assembly

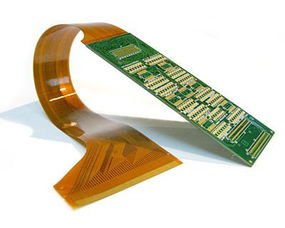

Rigid-flex PCB assembly is a cutting-edge technology that combines the benefits of rigid and flexible printed circuit boards into a single unit. This innovative approach to PCB design offers a wide range of benefits, making it an attractive option for manufacturers looking to streamline their production and assembly processes.

One of the key advantages of rigid-flex PCB assembly is its ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, rigid-flex PCBs allow for more compact and lightweight designs. This is particularly important in industries where space is at a premium, such as the aerospace and medical device sectors.

In addition to saving space, rigid-flex PCB assembly also simplifies the assembly process.

Traditional PCBs require multiple components to be soldered together, which can be time-consuming and labor-intensive.

With rigid-flex PCBs, however, the entire circuit can be integrated into a single unit, reducing the number of solder joints and potential points of failure. This not only speeds up the assembly process but also improves the overall reliability of the finished product.

Furthermore, rigid-flex PCB assembly offers greater design flexibility compared to traditional PCBs.

Because rigid-flex PCBs can be bent and folded to fit into tight spaces, designers have more freedom to create innovative and compact layouts. This flexibility allows for more creative and efficient designs, leading to improved performance and functionality in the final product.

Another benefit of rigid-flex PCB assembly is its durability and reliability.

Traditional PCBs are prone to damage from bending and flexing, which can lead to premature failure.

Rigid-flex PCBs, on the other hand, are designed to withstand repeated bending and flexing without compromising their performance.

This makes them ideal for applications where the PCB may be subject to mechanical stress or vibration, such as in automotive or industrial settings.

Additionally, rigid-flex PCB assembly can help reduce overall production costs.

While the initial investment in rigid-flex PCBs may be higher than traditional PCBs, the long-term savings in terms of reduced assembly time, improved reliability, and lower maintenance costs can more than offset the initial expense.

By streamlining the production process and improving the quality of the finished product, manufacturers can achieve greater efficiency and profitability.

In conclusion, rigid-flex PCB assembly offers a wide range of benefits for manufacturers looking to streamline their production and assembly processes. From reducing size and weight to simplifying assembly and improving reliability, rigid-flex PCBs provide a cost-effective and efficient solution for a variety of industries.

By embracing this innovative technology, manufacturers can stay ahead of the competition and deliver high-quality products that meet the demands of today’s fast-paced market.