Benefits of Rigid-Flex PCB Assembly

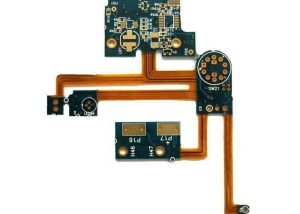

Rigid-flex PCB assembly is a technology that combines the benefits of rigid and flexible printed circuit boards into a single unit.

This innovative approach to PCB design offers a number of advantages over traditional rigid PCBs, particularly in terms of space utilization and functionality.

By integrating both rigid and flexible components into a single board, designers can create more compact and efficient electronic devices that are better suited to the demands of modern technology.

One of the key benefits of rigid-flex PCB assembly is its ability to maximize space utilization.

Traditional rigid PCBs are limited by their fixed dimensions and flat, two-dimensional design.

In contrast, rigid-flex PCBs can be bent and folded to fit into tight spaces or conform to the shape of the device they are installed in.

This flexibility allows designers to make the most of the available space, reducing the overall size of the device and improving its portability and aesthetics.

Another advantage of rigid-flex PCB assembly is its ability to improve the functionality of electronic devices.

By combining rigid and flexible components on a single board, designers can create more complex and sophisticated circuits that would be difficult or impossible to achieve with traditional rigid PCBs.

This increased functionality allows for the integration of more features and capabilities into a smaller package, making electronic devices more versatile and powerful.

In addition to maximizing space and functionality, rigid-flex PCB assembly offers a number of other benefits.

For example, the use of flexible materials in the construction of the board can help to reduce the risk of mechanical failure due to vibration or shock. This can be particularly important in applications where the device is subject to rough handling or extreme conditions.

Rigid-flex PCB assembly can also help to simplify the manufacturing process and reduce costs.

By combining multiple components into a single board, designers can reduce the number of separate parts that need to be assembled, leading to faster production times and lower labor costs.

Additionally, the use of flexible materials can help to reduce the need for complex wiring and connectors, further streamlining the manufacturing process.

Overall, the benefits of rigid-flex PCB assembly are clear.

By maximizing space utilization, improving functionality, reducing the risk of mechanical failure, and simplifying the manufacturing process, this innovative technology offers a number of advantages over traditional rigid PCBs.

As electronic devices continue to become smaller, more powerful, and more complex, rigid-flex PCB assembly will play an increasingly important role in meeting the demands of modern technology.

In conclusion, rigid-flex PCB assembly is a versatile and efficient technology that offers a number of benefits for electronic device designers. By combining the advantages of rigid and flexible PCBs into a single unit, designers can create more compact, powerful, and reliable electronic devices that are better suited to the demands of modern technology.

As the use of rigid-flex PCB assembly continues to grow, we can expect to see even more innovative and sophisticated electronic devices hitting the market in the years to come.