Benefits of Rigid-Flex PCB Assembly

In the ever-evolving world of electronics, the demand for smaller, lighter, and more durable devices continues to grow.

As a result, manufacturers are constantly seeking innovative solutions to meet these demands.

One such solution that has gained popularity in recent years is rigid-flex PCB assembly.

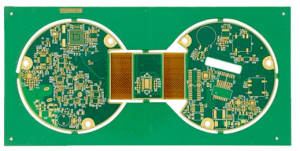

Rigid-flex PCBs combine the best of both rigid and flexible circuit boards, offering a unique combination of strength and flexibility.

This allows for more compact and lightweight designs, as well as increased durability and reliability.

In addition, rigid-flex PCBs can reduce the need for connectors and cables, further streamlining the design and assembly process.

One of the key benefits of rigid-flex PCB assembly is its ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, manufacturers can create more compact and lightweight designs.

This is particularly important in industries such as aerospace, automotive, and medical devices, where space and weight constraints are critical.

Another advantage of rigid-flex PCB assembly is its increased durability and reliability.

Traditional rigid PCBs are prone to damage from bending and flexing, while flexible PCBs can be more susceptible to wear and tear.

Rigid-flex PCBs offer the best of both worlds, with the rigid sections providing stability and support, and the flexible sections allowing for movement

and flexibility. This results in a more robust and reliable product that can withstand the rigors of everyday use.

In addition to size, weight, durability, and reliability, rigid-flex PCB assembly also offers cost savings and improved performance.

By reducing the number of components and connections, manufacturers can lower production costs and improve overall efficiency.

This can result in a more competitive product that meets or exceeds customer expectations.

Furthermore, rigid-flex PCB assembly allows for more complex and intricate designs that would be difficult or impossible to achieve with traditional PCBs.

This opens up a world of possibilities for designers and engineers, enabling them to create innovative and cutting-edge products that push the boundaries of technology.

Overall, the benefits of rigid-flex PCB assembly are clear. From smaller and lighter designs to increased durability and reliability, this technology offers a host of advantages for manufacturers and consumers alike.

As the demand for smaller, more powerful electronic devices continues to grow, rigid-flex PCB assembly is poised to become the future of electronics.

Its unique combination of strength and flexibility, along with its cost savings and improved performance, make it an attractive option for a wide range of industries. Whether you’re designing a smartphone, a medical device, or a satellite, rigid-flex PCB assembly offers a versatile and efficient solution that is sure to shape the future of electronics for years to come.