Benefits of Flex PCB

Flex PCBs and rigid flex PCBs are two popular choices in the world of printed circuit board design.

Both offer unique advantages and considerations that designers must take into account when choosing the right option for their project.

In this article, we will explore the benefits of flex PCBs and rigid flex PCBs, and discuss the design considerations that come with each option.

Flex PCBs, also known as flexible printed circuit boards, are designed to be flexible and bendable.

This flexibility allows for greater freedom in design, as the PCB can be shaped to fit into tight spaces or conform to the shape of the device it is being used in. Flex PCBs are also lightweight and durable, making them ideal for applications where weight and space are at a premium.

One of the key benefits of flex PCBs is their ability to reduce the overall size and weight of a device.

By using a flex PCB, designers can create a more compact and lightweight product, which is especially important in industries such as aerospace, automotive, and medical devices.

Flex PCBs also offer improved reliability, as they are less prone to mechanical failures due to their flexibility.

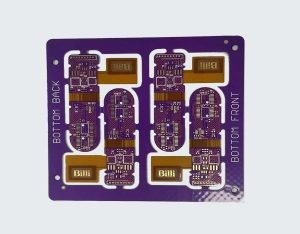

Rigid flex PCBs, on the other hand, combine the benefits of both rigid and flex PCBs.

These boards consist of a combination of rigid and flexible sections, allowing for greater design flexibility while still maintaining the structural integrity of a rigid PCB.

Rigid flex PCBs are ideal for applications where both flexibility and durability are required, such as in military and aerospace applications.

One of the key benefits of rigid flex PCBs is their ability to reduce the number of interconnects needed in a design.

By combining rigid and flexible sections into a single board, designers can eliminate the need for connectors and cables, reducing the overall complexity of the design and improving reliability.

Rigid flex PCBs also offer improved signal integrity, as the rigid sections provide a stable platform for high-speed signals to travel through.

When designing a flex PCB or rigid flex PCB, there are several key considerations that designers must take into account.

One of the most important considerations is the material used in the construction of the board.

Flex PCBs are typically made from polyimide or polyester, while rigid flex PCBs are often made from a combination of FR4 and polyimide.

The choice of material will depend on the specific requirements of the application, such as temperature resistance, flexibility, and cost.

Another important consideration when designing a flex PCB or rigid flex PCB is the number of layers needed in the board.

Flex PCBs are typically single or double-sided, while rigid flex PCBs can have multiple layers.

The number of layers will depend on the complexity of the design and the requirements of the application.

Designers must also consider the routing of traces and vias in the board, as well as the placement of components to ensure optimal performance.

In conclusion, both flex PCBs and rigid flex PCBs offer unique benefits and considerations that designers must take into account when choosing the right option for their project. Flex PCBs are lightweight, flexible, and durable, making them ideal for applications where size and weight are important.

Rigid flex PCBs combine the benefits of both rigid and flex PCBs, offering greater design flexibility and reliability.

By understanding the design considerations of each option, designers can make informed decisions that will result in a successful PCB design.